Integrated Domestic Production System Ranging from Pulp to Carton

A System for Domestically Handling the Entire Process from Pulp to Printing and Processing

By conducting all processes from pulp production to the lamination of paperboard at our plants in Japan, we have established high quality control and stable product supply.

Wide Range of Cartons

We provide 500ml and 1,000ml cartons with spout holes for cap attachment, and we also offer caps with a tamper-evident (TE) ring and without a TE ring.

Beautiful Cartons with Japan Quality

We use only high quality base paper manufactured in Japan under strict quality control using sustainable raw materials (e.g., wood chips)

Beautiful Forming

Exceptional Printability

Flexible Filling Suitability

Maintain Good Flavors

Safe and Reliable Cartons

Oji Group provides safe and high-quality products by ensuring the safety of each process, including the production of environmentally friendly and sustainable raw materials, as the Oji Group is responsible for the entire manufacturing process.

Raw Material

Our strict quality control in accordance with Japanese standards enables us to provide safe and reliable base paper.

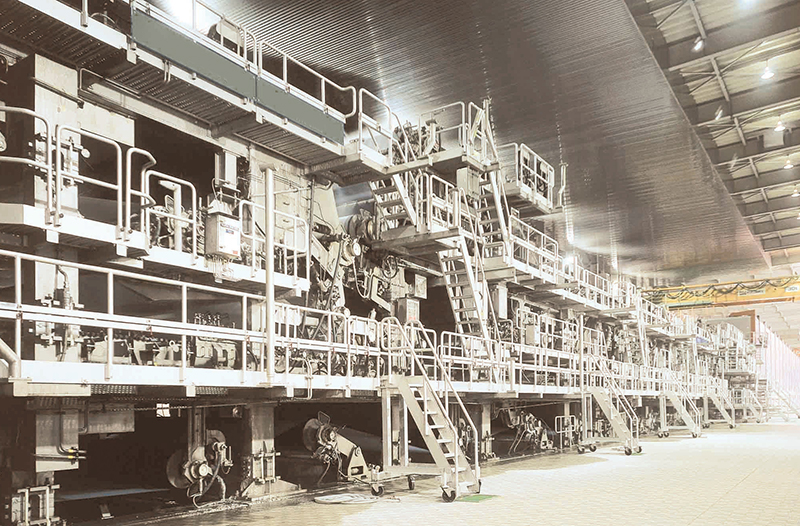

Encompasses the Entire Production Process, from Making Paper to Processing Cartons

Oji Group has become capable of handling the entire process from pulp to milk cartons in Japan by making the lamination for the layer structure of milk cartons, which had been limited to overseas, practical in Japan and combining it with existing technologies for paper manufacturing.

This enables a quick response to last-minute orders and any problems that may arise. It also facilitates a high level of quality control and benefits such as reduced transportation costs.

Utilization of Forest Certification Programs

Oji Group also manufactures FSC™ certified products (FSC™ C014119, etc.), the use of which indirectly contributes to preserving forests.

These products use woodchips that meet FSC™ requirements. We have acquired FSC™-FM certification*1 for its overseas forest plantations and FSC™-CoC certification*2 for its manufacturing and processing operations. Acquiring integrated certification from forests to converting plants enables Oji Group to offer a wide range of FSC™ certified products, from intermediate products to end products such as photocopying paper and paper for household use.

*2 CoC certification: Confirmation of management on processing and distribution of produced wood

Safety and Accountability

We also provides the safety information to customers.

Case study

王子のミルクカートンの導入事例「DM社の場合」

ミルクカートンだけを使っているお客様(サイトオープンに間に合ったら入れる、間に合わなかったらComing soon」にしておく?